Master Batches

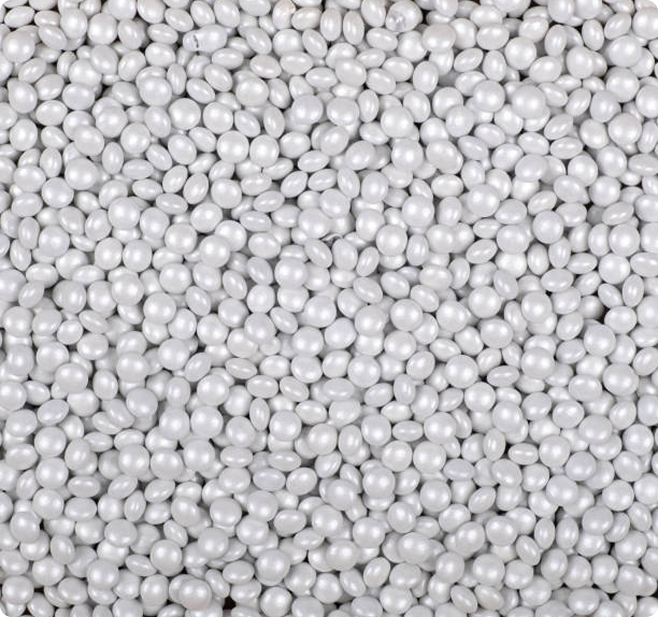

Masterbatches are concentrated mixtures of pigments, additives, or other components encapsulated into a carrier resin and used to color or enhance the properties of plastics during manufacturing. Typically added in small amounts to raw polymers, they provide benefits such as improved UV resistance, strength, appearance, and processability while ensuring consistent dispersion. Masterbatches are available in various types, including color masterbatches (like black, white, and pearl), additive masterbatches (such as UV stabilizers and antioxidants), filler masterbatches (like calcium and talc), and functional modifiers. Widely used in industries like packaging, automotive, electronics, and consumer goods, masterbatches offer a clean, efficient, and cost-effective way to customize plastic materials.